for Tubo rectangular/Tubo circular/Circle Tube/Tubo cuadrado/Tubo elipse/Perforation

¡@

Tube Punching Machine for Rectangle Tube/Round Tube/Circle Tube/Square Tube/Ellipse Tube

IW500DL NC Digital Dual Cylinder Linear Pipe/Tube Punching Machine (Puncturing Machine with Servo Motor)/Tube Puncher

About us | Machinery | NEW | English | Contact us

¡@

¡@

¡@

Application: (SPECIAL DESIGN OR BIGGER PRODUCT SIZE IS WELCOME)

Round Tube: 1"~6inch

(25.4 * 150mm)

Round Tube: 1"~6inch

(25.4 * 150mm)

Square Tube: 25*25~106*106mm

(1"~4.17inch)

Square Tube: 25*25~106*106mm

(1"~4.17inch)

Rectangle/Oblong

Tube: 20*40~75*130mm

Rectangle/Oblong

Tube: 20*40~75*130mm

Ellipse Tube: 20*40~75*130mm

Ellipse Tube: 20*40~75*130mm

¡@

Especificaciones: (Diseños especiales son bienvenidos)

1. Alimentacón automática.

2. Servo Alimentar en posición, tenedor para el material longitud: 7000mm (diseños especiales o tubos más largos son aceptables). Tubos de differentes longitudes son bienvenidos.

3. Tipo de perforación de agujero/punzonados: agujero/punzonado ciego, gujero a través.

4. Opción 1: Con eje Y (alimentar) y eje B (rotar). El servo motor con abrazadera para sujetar y rotar el tubo para que sea perforada los agujero/punzonados desde differentes ángulos.

5. Opción 2: Con un aparato extra que jala el tubo para que pueda punzonar, perforar, fresar la parte final del tubo.

¡@

¡@

4"*8"

Tubo rectangular con agujeros/punzonados a traves (con salida)

4"*8"

Tubo rectangular con agujeros/punzonados a traves (con salida)

Features

¡@

TFT Human Machine Touch Interface Display Control Systems: TFT human machine interface display, touch controllable display setting, digital control systems, servo motor position scaling precision, and modular memory function.

Punching Motion types:

2-1. Single Punching Operation

2-2. Irregular Interval Punching (You can set irregular C/C distance between holes)

2-3. Regular Interval Punching. (You can set regular C/C distance between holes)

Production Capacity: 20000-40000 holes/8 hours (Single Line)

The machine have an Auto feeding Function for the tubes. Forward and Backward the tubes is moved by Servo Motor. You can adjust the punching speed and the feeding speed faster. Tube will be clamped by Hydraulically.

For thru punch, the scrap from top hole and scrap from bottom hole will go down to the Scrap-Box.

Operational Function : Jogging/Automatic Functions

Oil Hydraulic System : step-less operation adjustment, hydraulic loops designed with zero load, combined with extremely low frequency oil pump motor, effectively reduced noise, increased motor efficiency and service duration

Whenever the oil cylinder is moving downward, the machine is designed with hydraulic difference driving loops rated at high or low RPM. It is also featured with high speed downward moving, low speed processing and hi-speed position resume. It is available to increase the formation stability of work pieces during puncturing. In addition to increasing the activation speed, it can effectively reduce HP load to save electrical energy.

The electrical control system is designed with human machine interface150mm (Stroke available for positioning) the mold set is designed with 600mm in depth avail-able for forward and backward 150mm moving accessibility. Our machine is designed with the Italy-made Optic Digital Ruler (LCD display) with high precision.

Our machine is adopted with Japan-made servo motor driving devices and the feed-in and receiving speed can be set to high speed and high precision to enhance the productivity.

It is featured with sufficient clamping force of clamping hydraulic cylinders and the position of word pieces is stable and uneasily loose off.

Applications: Square Tube, Rectangle Tube, Ellipse Tube and Round Tube punching.

Servo Feed-in Positioning Frame length :4000mm~7000mm or more (Depend on customer's request)

Machine Body :

1500mm (W)*8200mm (H)*2500mm ;Total Weight :5Ton

CNC/NC Tube Pipe Drilling Machine

IW50DL NC Digital Dual Cylinder Linear Pipe/Tube Punching Machine (Puncturing Machine with Servo Motor) for Rectangle Tube/Round Tube/Circle Tube/Square Tube/Ellipse Tube/Perforation

Автоматический станок для пробивки труб

IW500DL.

Низкочастотный гидравлический привод станка эффективно снижает шум и повышает

производительность и срок службы двигателя.

Цифровая система управления с модульным устройством памяти снабжена TFT

сенсорным дисплеем и обеспечивает высокую точность позиционирования отверстий.

Режим работы автоматический или командный, пробивка может осуществляться в

одиночном режиме, непрерывном с равномерными промежутками, непрерывном с

неравномерными промежутками между отверстиями.

Конструкция гидравлической станции позволяет настраивать её на оптимальный,

энергосберегающий режим работы.

Машина оснащена электронным детектором-позиционером итальянского производства, с

выводом поступающих данных на ЖК-дисплей.

В станке применяются сервоприводы японского производства, что позволяет

добиваться высокой скорости и отличного качества работы.

Область применения: профильная и круглая труба.

Технические характеристики:

Максимальная длина трубы ........................... до семи метров

Мощность системы .......................................5.6кВт

Давление пробивки ......................................50тн

Габариты ............................................8200мм х 1500мм х 2500мм

Вес ............................................................5000кг

¡@

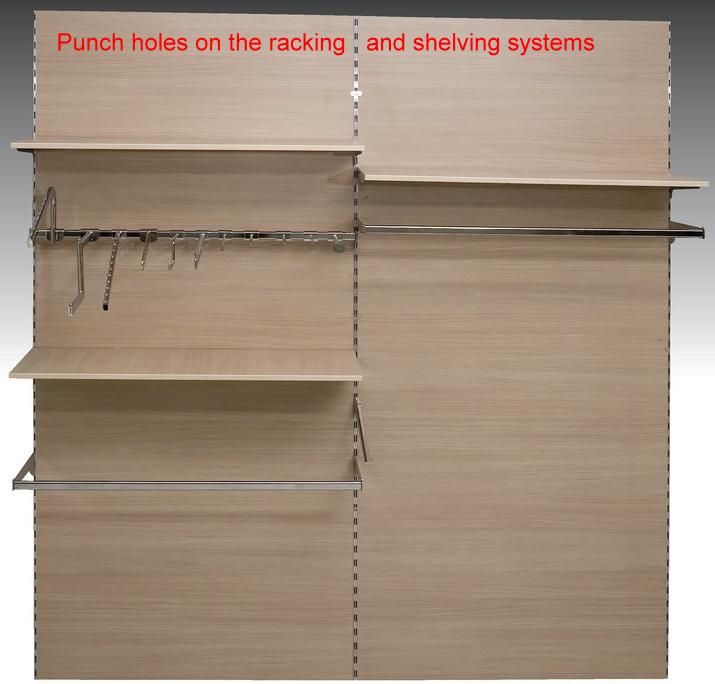

Ladders / Racking and Shelving Systems