|

Features:

★

TFT human machine

interface display ,touching controllable screen setting, digital control

systems, servo motor positioning dimension precision, attached with modular

memory functions.

★

Structure: The body frame

is designed with the composite assembly with robust and endurable spare parts.

★

Operation Function:

Jogging/automatic Functions

★

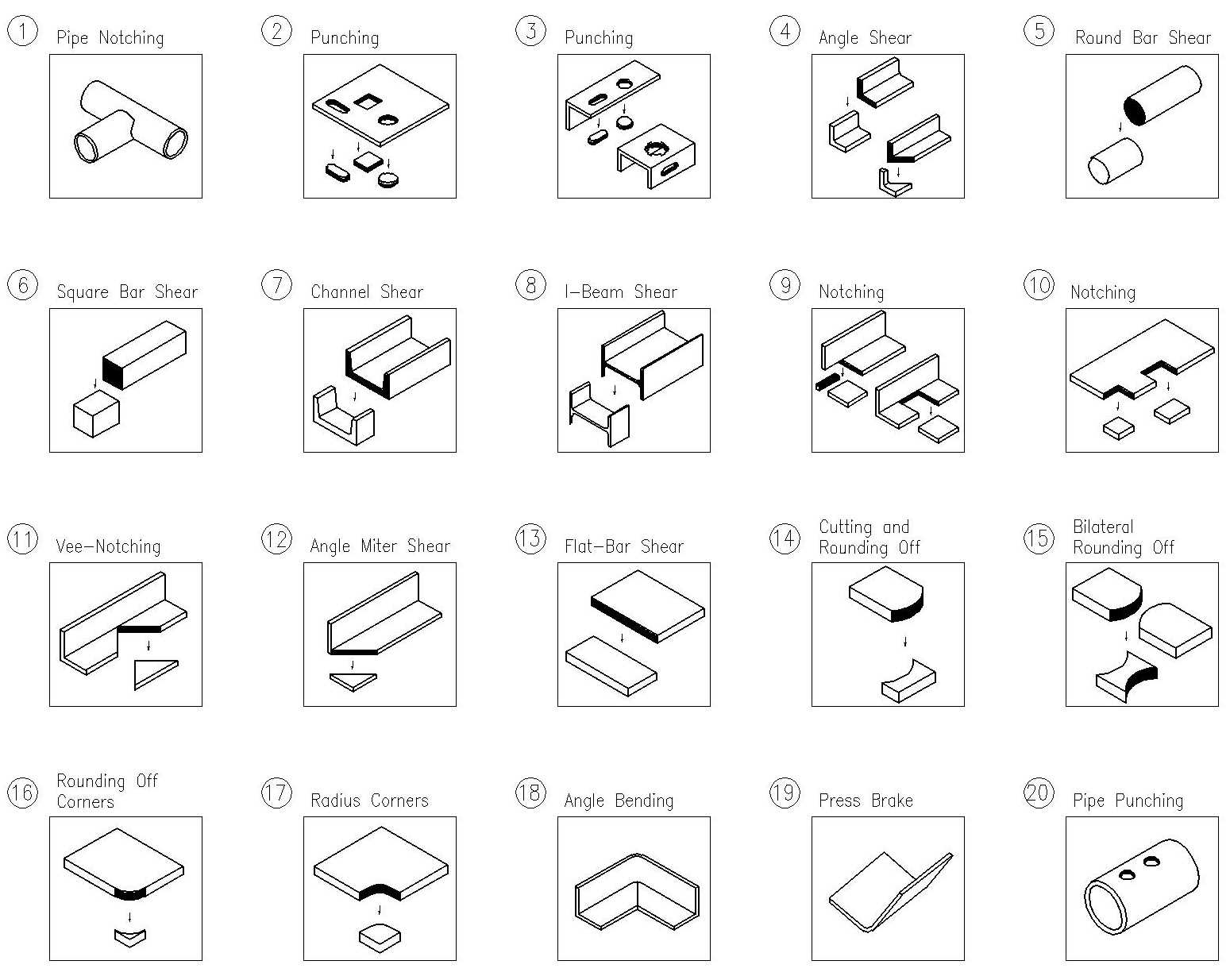

Engineering Motion

Classification:1、single

punching operation, 2、irregular

interval punching ,3、regular

interval punching

★

Oil Hydraulic System

:step-less operation adjustment ,hydraulic loops designed with zero load

,combined with extremely low frequency oil pump motor ,effectively reduced noise

, increased motor efficiency and service duration

★

Whenever the oil

cylinder is moving downward , the machine is designed with featured like low

RPM. It is also featured with high speed down ward moving ,low speed processing

and hi-speed position resume so that it is available to increase the formation

stability of work pieces during puncturing.

★

The electrical control

system is designed with the human machine interface .The distance adjustment is

designed with scaling positions, start distance marks, low speed position marks,

and low extremity position .it is available for precise and comprehensive

operation.

★

Hydraulic Cylinder

Stroke 150mm (Stroke

available for positioning)the

mold set is designed with 600mm in depth available for forward and backward

150mm moving accessibility .Our machine is designed with the Italy –made digital

scale (LCD Display) with high precision.

★

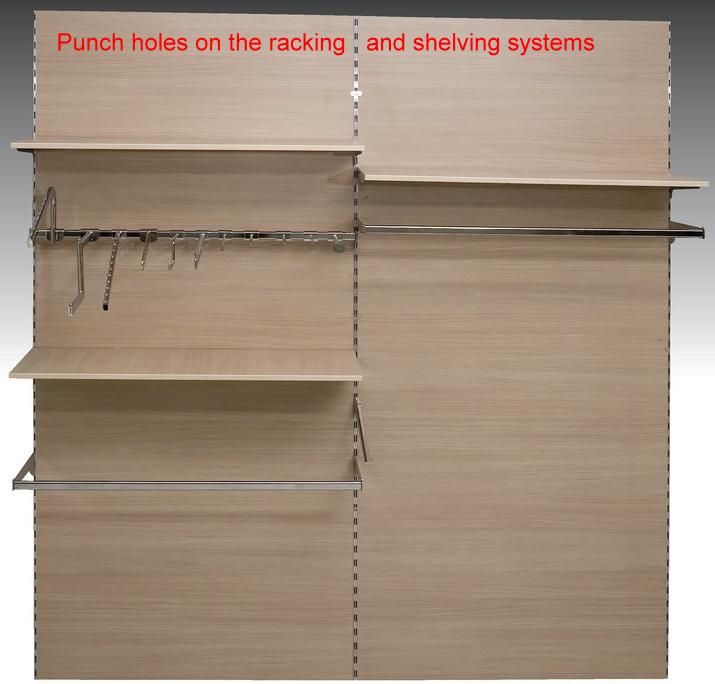

Application :Angle

steel ,grooved steel and flat steel cutting(45°)and

puncturing

★ Servo Position Frame

Length :3000mm Feed –in Frame Length:2000mm (Standard)

★

Body:1500mm (L):6500mm

(W):2000mm

(H)Total

Weight: 6.8T

|

Round

Tube:

Round

Tube: Square Tube:

Square Tube: Rectangle/Oblong

Tube:

Rectangle/Oblong

Tube:  Ellipse Tube:

Ellipse Tube: