|

Features:

-

17 Tons Hydraulic Cylinder * 3 sets (Top / Left /

Right)

-

Three Hydraulic Cylinders Automatic Tube Punching

Machine with 3 Punching Heads

(2 Horizontal and 1 Vertical) and Rotation Servo Motor

(option).

-

This machine

can punch 9 kinds (or 7 kinds or 3 kinds) different holes (or above) on the same

profile/channel/tube.

Coupled / Combined with a special design patent shifting feature, it is able to punch

from 3 to 9 different tool shapes in 3 different

directions (vertically and from both horizontal sides). So

you can punch DIFFERENT Hole Size and Shape on UPN

Channel or any Profile without change the mold.

-

Option : With

Y-Axis [FEED] & B-Axis [Rotate] Servo Motors which can

clip the tube & ROTATE the tube to punch the holes in

the different angles

-

Option :

It allows to punch at the edges of the tube material and

leaving practically no leftover or crop waste in the

stock material.

-

Option : Automatic

Loading and Unloading System

-

With 3 sets Power Press (Punching Device with Hydraulic

Cylinder) + Dies + Auto Feeder

-

FULL

automatic punching for C-Channel

and

TUBES

-

NC Digital Dual Cylinder Linear Pipe/Tube Punching

Machine (Puncturing Machine with Servo Motor) for

Rectangle Tube/Round Tube/Circle Tube/Square

Tube/Ellipse Tube/Perforation

-

Punching Capacity: Hydraulic punching machine with 2 Horizontal Heads and 1

Vertical Head, each having maximum power as follows:

1. Top Vertical Punching Head

2. Left Horizontal Punching Head

3. Right Horizontal Punching Head

-

Servo Feed-in Positioner Frame for Material Length:

7000mm (SPECIAL DESIGN OR LONGER TUBES IS WELCOME) for Different variable

Lengths of the tubes

-

Punching Types for

Holes:

Blind Hole, Through Hole,

Perforation

-

Станки для пробивки отверстий в

трубах и профилях

Specifications:

-

TFT HMI (Human Machine

Interface) Touch Display Control Systems: TFT human machine interface

display, touch controllable display setting, digital control systems, servo

motor position scaling precision, and modular memory function.

-

Punching Motion

types:

|

2-1. Single Punching Operation |

|

2-2. Irregular Interval Punching (You can set irregular Center to

Center distance [pitch] between holes) |

|

2-3. Regular Interval Punching. (You can set regular Center to

Center distance [pitch] between holes) |

-

Production Capacity:

2 seconds /hole (Single Line)

-

The machine have an

Auto feeding Function for the tubes/profiles/channels. Forward and Backward the tubes is moved

by Servo Motor. You can adjust the punching speed and the feeding speed

faster. Tube will be clamped by Hydraulically.

-

For thru punch, the

scrap from top hole and scrap from bottom hole will go down to the

Scrap-Box.

-

Operational Function

: Jogging/Automatic Functions

-

Hydraulic Oil System

: step-less operation adjustment, hydraulic loops designed with zero load,

combined with extremely low frequency oil pump motor, effectively reduced

noise, increased motor efficiency and service duration

-

Whenever the

hydraulic oil

cylinder is moving downward, the machine is designed with hydraulic

difference driving loops rated at high or low RPM. It is also featured with

high speed downward moving, low speed processing and hi-speed position

resume. It is available to increase the formation stability of work pieces

during puncturing. In addition to increasing the activation speed, it

can effectively reduce HP load to save electrical energy.

-

The electrical

control system is designed with human machine interface 150mm (Stroke

available for positioning) the mold set is designed with 600mm in depth

avail-able for forward and backward 150mm moving accessibility. Our machine

is designed with the Italy-made Optic Digital Ruler (LCD display, option) with high

precision.

-

Our machine is

adopted with TAIWAN-made servo motor driving devices and the feed-in and

receiving speed can be set to high speed and high precision to enhance the

productivity.

-

It is featured with

sufficient clamping force of clamping hydraulic cylinders and the position

of word pieces is stable and uneasily loose off.

-

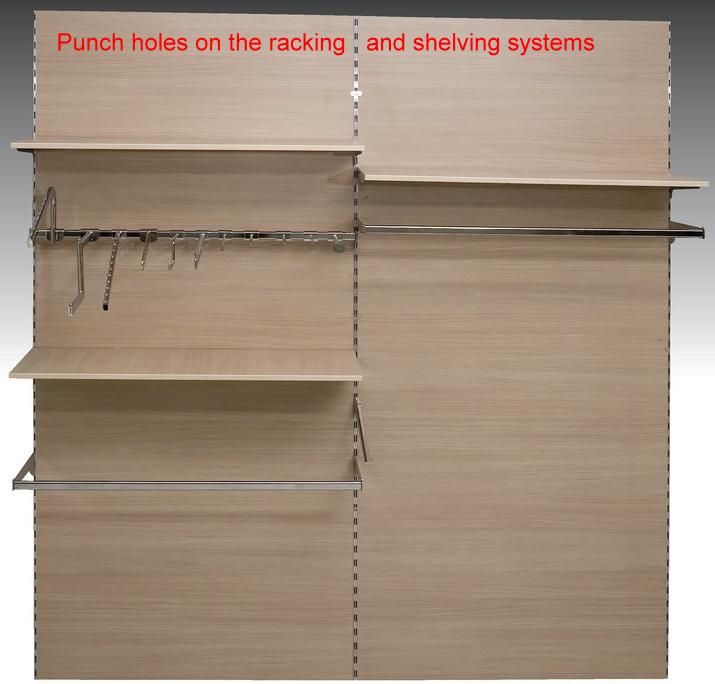

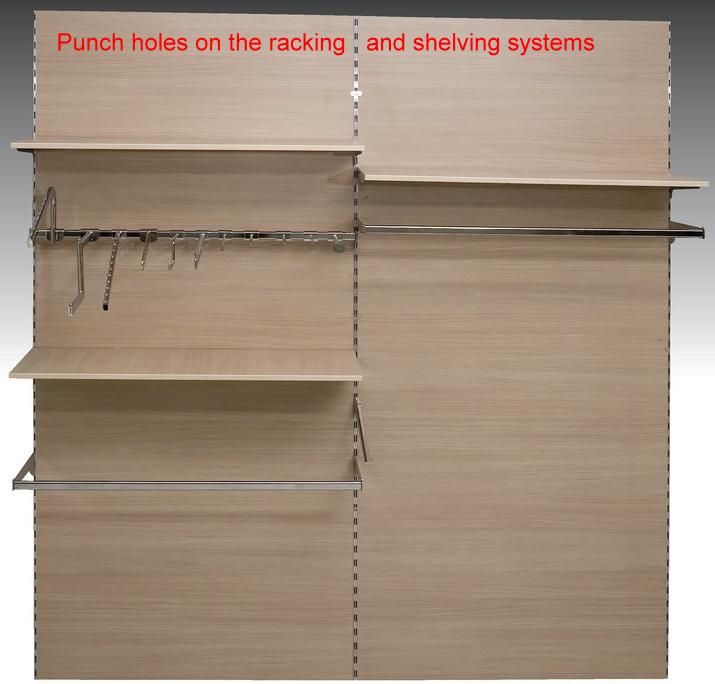

Applications: Square

Tube, Rectangle Tube, Ellipse Tube and Round Tube punching.

-

Servo Feed-in

Positioning Frame length :4000mm~7000mm or more (Depend on customer's

request)

-

Machine Body : 1500mm

(W)*8200mm (H)*2500mm ;Total Weight :5Ton

Application

:

Our Tube Punching Machine can save UNLIMITED

punching programs to USB Disk. And our Tube Punching Machine is suitable for the

Frames, Supermarket Shelving, Department Stores, DISPLAY SYSTEM, Supermarket

Display Racks, Fencing and Handrails, Form work, SCAFFOLDING, outdoor play

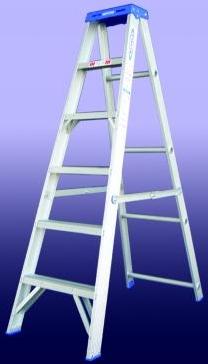

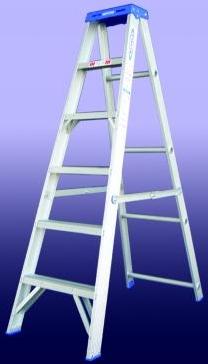

equipment (ladders) project, Furniture for Home / Kids folding deck chair /

beach chair , Shop fitting, Furnace, TV-brackets, Furniture production, Stand in

the Kitchen Accessories, Pallet Rack Systems, Cantilever Racks, Pushback Racks,

Supermarket Racks, Pallet Rack Systems, Gas Burner, Automotive Industry

(Dashboard), Radiators, Furniture, parts of the sofas (beds), Electrical Power

Transmission Poles (Tubular Poles and Lattice Poles),Towers (Telecommunication

Lattice Towers and High Tension Power Transmission Towers), Supermarket

Shelving, Shelving System, Working with stand in the supermarket, Construction

industry, the Office Furniture, robust and safe Shop fitting solutions, Frame,

playground equipment, Table Leg, Table type, Department Stores, Plant Shelves,

Scaffolding (Ring Lock & CUP Lock), Display Stand, Tours, Frame Systems, Props,

Accessories, Horse stalls, Supermarket Shielding, Mobile Shelving System,

Schools (tables and chairs), Poultry Building System, Cable Tray, the part of

V.C.D. (Volume Control Damper) for Central, Decorative Shelf and Hanging Systems

and its components, Bed, Ladders, Truck Body Builders, Metalworking Industries

Manufacturing for Automotive Manufacturing, Gas Stove, Power Energy and

Electrical Wire Distribution, Solar System, Racking and Shelving and base of

your Custom Signs, Electronic Displays, Resorts & Casinos, Outdoor Media and

Repairs & Maintenance, High Volume and different purpose Punching for Square

Tube / Rectangle Tube / Round Tube / Circle Tube / Ellipse Tube / Perforation

and much more.....so you can expand your business to many fields.

MOBILE SHELVING SYSTEM,

Bed, Furniture, Scaffolding (Ring Lock & CUP Lock, Tours, Frame Systems,

Table type, Props, Accessories), LADDERS, truck body

builders, display stand, metalworking industries manufacturing for

Automotive Manufacturing, Gas Stove, power energy and electrical

wire distribution, Racking and Shelving and base of your Custom

Signs, Electronic Displays, Resorts & Casinos, Outdoor Media and

Repairs & Maintenance, high volume and different purpose punching

for Rectangle Tube/Round Tube/Circle Tube/Square Tube/Ellipse

Tube/Perforation and much more......

|

solar panel

MORE

|

Fence/Fencing/Windows |

Metal Scaffolding making machine

MORE

|

Racking

and

Shelving System

MORE

|

Ladders |

|

|

|

|

|

|